Category

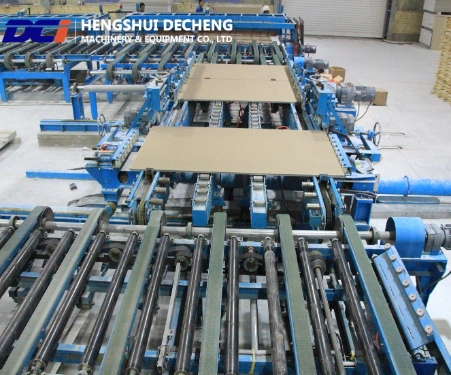

China Supplier Paper Surface Gypsum Board Processing Plant

Introduction of Paper Surface Gypsum Board Processing Plant: 1. Annual output: 2million to 30 million sqm(based on thick

Basic Info

| Model NO. | DCIB050 |

| Product Type | Gypsume Plate Production Line |

| Automatic Grade | Automatic |

| Power Source | Electric |

| Screw Design | Single-Screw |

| Certification | ISO, ISO 9001:2008 |

| Condition | New |

| Customized | Customized |

| Application | Construction Material |

| Automation | Automatic |

| Tolerance | 1.0mm |

| Type | Gyspum Board Production Line |

| Product | Gypsum Board |

| Brick Raw Material | Natural Gypsum Powder |

| Capacity | 2million Sqm/Y-30 Million Sqm/Y |

| Fuel | Natural Gas, Coal, Heavy Oil, Diesel |

| Service | Engineer Oversea Service |

| Transport Package | Seaworthy Packing |

| Specification | ISO9001 |

| Trademark | DCI |

| Origin | China |

| HS Code | 847480901 |

| Production Capacity | 4 Sets Per Year |

Product Description

Introduction of Paper Surface Gypsum Board Processing Plant:1. Annual output:

2million to 30 million sqm(based on thickness of 9.5mm gypsum board)

2. Working time: 24hours/day and 300 working days/year

3. Raw material: Gypsum powder, shielding paper, modified starch, foaming agent, glue

4. Fuel: Natural gas, diesel, heavy oil or coal

5. Product quality and specification:

1) The product is in compliance with National Standard GB/T9775-2008

2) Product specification:

Length: 2400mm~3600mm

Width: 1200mm or 1220mm

Thickness: 8mm-20mm

6. Main process:

1)Raw material blending;

2)Shaping;

3)Wet board/panel conveying;

4)Drying;

5)Dry board/panel conveying;

6)Finished product stacking and storage.

7. Main technology:

The production line adopts special designed hot air stove heating system

8. Consumption of raw materials

(Based on 9.5 mm gypsum board for reference)

| Gypsum | 6.8kg/m2 |

| Shielding paper | 0.48kg/m2 |

| Modified starch | 0.035kg/m2 |

| Foaming agent | 0.008kg/m2 |

| Glue | 0.005kg/m2 |

| Fiberglass (optional) | 0.025kg/m2 |

| Electricity | 0.3kwh/m2 |

| Water | 4.8kg/m2 |

| Heavy oil (11000kcal/kg) | Heat consumption~3800kcal/m2 |

| Natural gas (8500kcal/ m3) | Heat consumption ~3800kcal/m2 |

| Item | Consumption |

| Gypsum powder(semi-hydrated gypsum CaSO4·1/2H2O) | 7.5kg/m2 |

| Protective paper | 0.4-0.48kg/m2 |

| Gypsum board adhesive | 0.052kg/m2 |

| Foaming agent | 0.011kg/m2 |

| Glue | 0.005kg/m2 |

| Electricity | 0.4kwh/m2 |

| Water | 5.9-6.2kg/m2 |

| Natural gas (8200 kcal/ m3) | 0.31 m3 /m2 |

| Compressed air | 0.18m3/m2 |

Till now, we've manufactured and supplied complete sets of machine lines to Russia, Oman, Uzbekistan,United Arab Emirates, Iran.

9.Payment conditions:

A. Payment terms: 30% T/T in advance; 70%L/C or T/T

B. We can provide quality guarantee;

C. Kunlun bank account available to make convenient for Iranian clients

Welcome to visit and enquiry us!