Category

Small Scale Energy Efficient LNG Ngl Processing Unit with High Quality and Favorable Price Oxygen Nitrogen

Product Specifications Skid Mounted LNG Production Equipment Liquefied natural gas (LNG) is widely used as clean energy.

Basic Info

| Usage | Hydrogen, Nitrogen, Oxygen |

| Purpose | Gas Manufacturing |

| Application Fields | New Energy |

| Machine Size | Large |

| Condition | New |

| Specification | 40000 KG |

| Trademark | Greenfir |

| Origin | Chengdu, Sichuan |

| Production Capacity | 20 Sets Per Year |

Product Description

Skid Mounted LNG Production Equipment

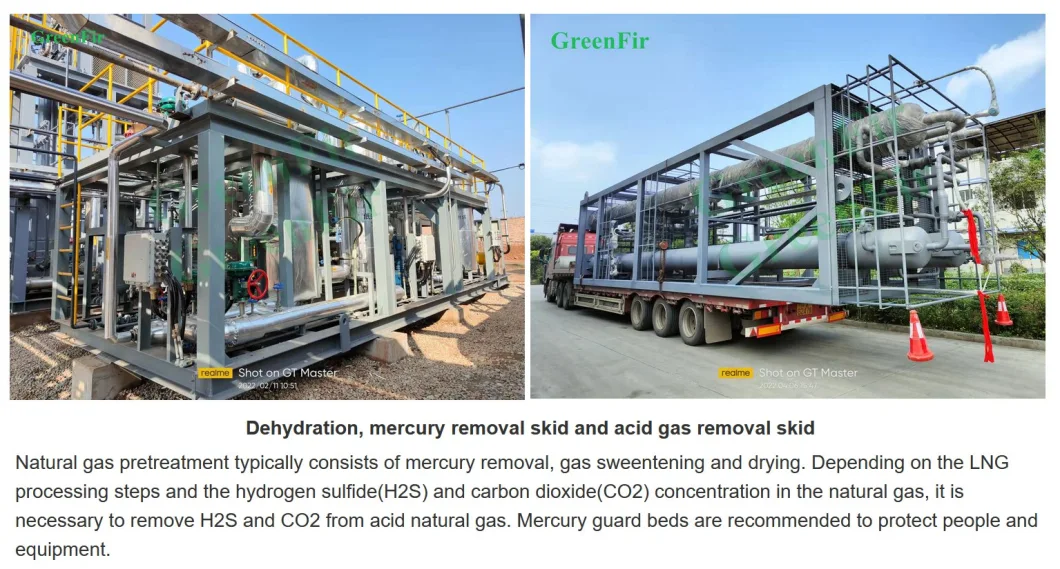

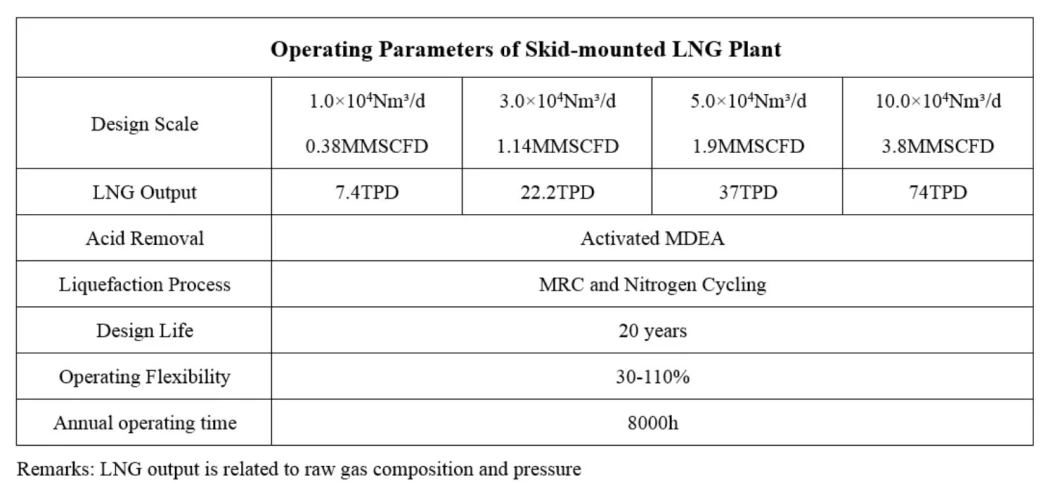

Liquefied natural gas (LNG) is widely used as clean energy. GreenFir owns a variety of self developed natural gasliquefaction technologies, such as mixed refrigerant cycle (MRC) and N2 cycle. And GreenFir develops optimizecsingle-stage mixed refrigeration (SMR), C3 pre-cooled mixed refrigeration (C3MR) and double mixed refrigerationDMR) considering different cooling principles and working conditions. LNG plants are typically sized to produce from 20to 1440 tons per day of LNG.

Technical Process

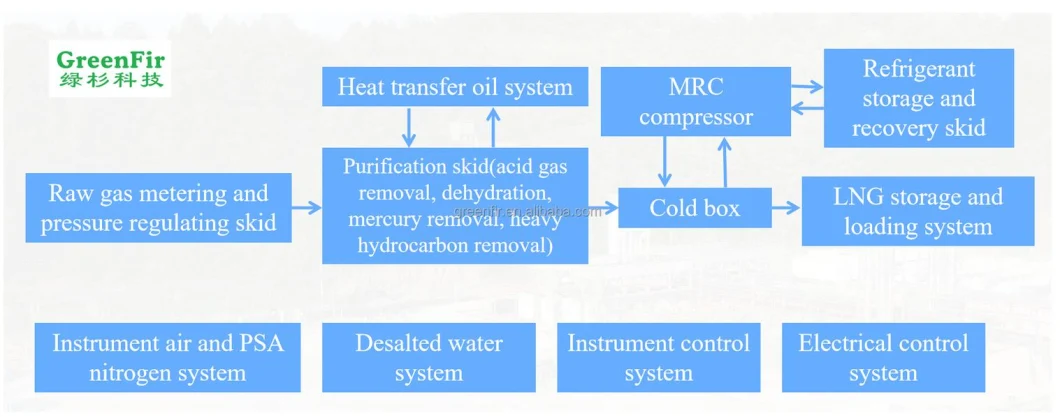

The small skid-mounted LNG lnt process includes raw gas meterind and pressure redulation svstem. raw oaspurification, liquefaction, LNG storage, central control system, safety system, analysis and testing system, electricacontrol svstem and public works: instrument air and PSA nitrogen svstem. heat transfer oil svstem. desalted watersvstem. , etc. The refrigerant svstem includes refricerant compression, refrigerant storage, refrigerant recovery svstemetc.

The pretreated raw gas from the boundary area enters the raw cas metering and pressure requlating skid, and theadiustment range is 0~+110%: after pressurization, it enters the purification skid deacidif cation. dehvdration. anomercury removal). The purified raw oas enters the cold box. and it becomes LNG-162C) after liguefaction.